Your tunnel projects will benefit from our expertise in a range of fields and from state-of-the-art testing and calculation resources. Our global approach will cover every step in your project.

We substantiate the expected fire performance of your products and works for any thermal load (ISO-834 standard fire curve, HCM, RWS, Eureka, real fire).

Your projects

are our responsibility.

All our laboratory tests are carried out at our facility in Épernon (60 km from Paris) which is equipped with handling systems suitable for large units (25-tonne overhead travelling crane).

The Fire Testing Centre is:

• approved by the French Ministry of the Interior for fire-resistance testing,

• accredited by COFRAC (French Committee for Accreditation) for fire-resistance testing (Accreditation No. 1-0001 – scope available at www.cofrac.fr).

Fire performance of civil engineering works.

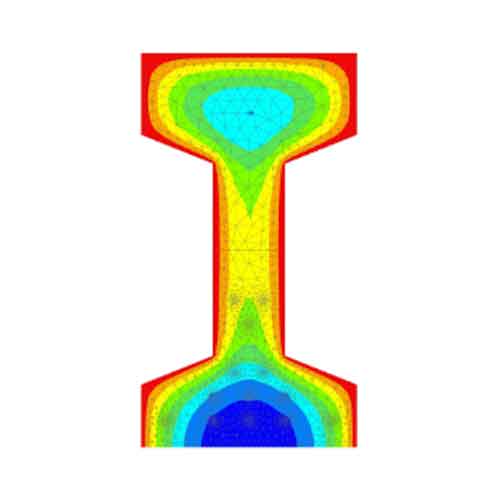

• Numerical appraisal of fire performance of structures

– Computer simulation with finite-element resources

– Advanced calculations as per Eurocodes and other reference standards (Model Code, etc.)

– Assessment of stresses in works to take account of spalling.

• Verification of tendency of concrete to spall

– Objective: to check there is sufficient sacrificial cover in conformity with design

– Characterization and assistance for selecting concrete mix designs

– Mix-design tests and suitability test representative of the works (as per CETU (French Tunnel Research Centre) guideline documents)

– Measurement of spalling and temperature contours.

• Passive fire-protection test

– EN 13381 series of standards, CETU HCM test method

– Characterization of protection products

– Measurement of temperatures at protection/structure interface.

• Fire-resistance testing of compartmentation elements

– Large partition walls (up to 6 m x 4 m) as per EN 1364-1

– Penetration seals as per EN 1366-3

– Linear joint seals as per EN 1366-4.

Segment

design check.

design check.

• Ambient and high-temperature characterization of steel-fibre-reinforced concrete (SFRC)

• Full-scale bending testing of segments

• Full-scale testing of segments under thrust of TBM pads

– Thrust stand: up to 1,800 tonnes.

• Full-scale fire-resistance testing of segments

– Variable vertical and horizontal loading during test

– Strain and temperature measurement

– Configurations with segment seals.

Fire resistance

of equipment.

• Fire-resistance testing of ventilation and smoke-exhaust equipment

– Ventilation and smoke-exhaust ducts (EN 1366-1/-8/-9)

– Fire and smoke-control dampers (EN 1366-2 and EN 1366-10).

• Fire-performance testing of sound traps (mufflers) and registers

– Our airflow test rig:

Extraction flowrate: 100,000 m3/h

Internal dimensions up to 4 m x 3 m.

• Fire-resistance testing of fire doors

– EN 1634-1

– Substantiation for large doors

– Testing bay up to 6 m x 4 m.

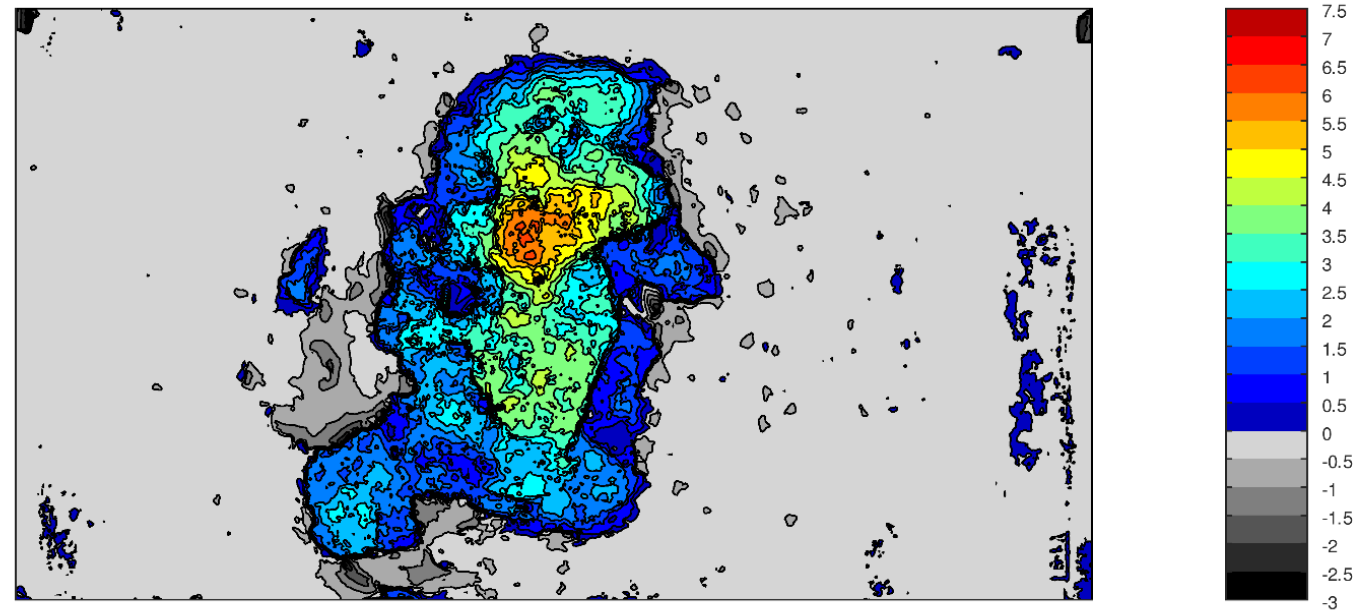

In situ testing and measurement:

evaluation of ventilation

and smoke-exhaust systems.

evaluation of ventilation

and smoke-exhaust systems.

• Special metrology for thermal and fluid dynamics

• Controlled generation of smoke and heat, adapted to the type of structure and smoke-exhaust strategy

• Measurement and recording: gas velocities, temperature, pressure, sound levels, weather conditions, HD videos, video recording with thermal-imaging cameras.

• Expert appraisal of results.

![shutterstock_1263924991 [Converti]-01](https://www.cerib-feu.com/wp-content/uploads/2021/08/shutterstock_1263924991-Converti-01-1.png)